How To Make a Jacuzzi Cover

First of all, you need to measure the Jacuzzi for which you want to make the cover.

Jacuzzi Covers have a few measurements that need to be taken into consideration in order for the Jacuzzi Cover to fit correctly once it comes back from the manufacturer. If your Jacuzzi Cover is square and has no rounded corners then you just measure the length and width of the Jacuzzi and make sure that you specify the position of the Switches on the drawing, the manufacturer will then leave an indentation for the switches.

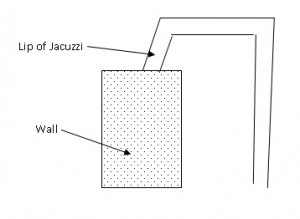

The Jacuzzi Cover needs to be measured from the outer lip of your Jacuzzi to the outer lip on the opposite side. The measurements must be taken till the bottom part of the lip, the part that touches the actual wall or wooden surround.

Depending on the type of installation it is important to understand that the Jacuzzi Cover has a Skirt that seals the heat in. If this skirt doesn’t fit right, then it drastically reduces the Jacuzzi Covers ability to insulate. Below is a picture of a nice fitting skirt.

In some cases, the installation is of such a kind that the skirt must either be very short or it must be cut away once the cover is in place. The shorter the skirt the less insulation you will have.

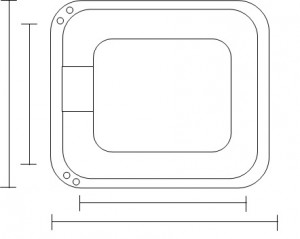

If your Jacuzzi Cover has rounded corners, then it is advisable to measure where the corner starts and ends. This will give the manufacturer clear instructions on how to manufacture your custom Jacuzzi Cover.

If you measure your Jacuzzi Cover wrong, then the manufacturer will not take responsibility if the cover doesn’t fit.

Once you have the measurements, you can choose a color for your Jacuzzi cover. Just remember that if your Jacuzzi Cover is going to be exposed to rain or sun, then it is better to use PVC, which is water resistant and UV protected.

Vinyl Covers have a much wider range of colors to choose from, although manufacturers and suppliers have limited their range of colors due to lack of demand on certain product colors. PVC has about 6 primary colors to choose from, which incl. red, yellow, blue, green, white and black.

You can use the color chart below, to select a color for inside Jacuzzi Covers. Please Note: exact colors may differ due to color resolution on your computer and also because a certain color range no longer gets manufactured and the new color is maybe a few shades darker or lighter.

Due to the wide variety of Jacuzzi makes and models purchased from different suppliers and manufacturers country wide, we have acquired a whole collection of templates from which we can cut Jacuzzi Covers. The next step in the process of manufacturing a Jacuzzi Cover, is to make a jig or pattern, from which you can then cut the different panels and strips which will later be sewed together.

An industrial type sewing machine should be used to stitch the material together.

If your stitching is very neatly done, the Jacuzzi Cover will look professional. Rushing the job usually leads to the Jacuzzi Cover looking shabby and cheap. Taking pride in what you do always creates a good impression and has earned companies like Nike, Apple and other manufacturers huge profits and worthy reputations as quality products.

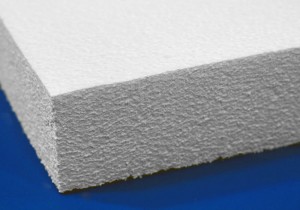

Once you have stitched all the panels together, the next would be to buy the polystyrene that forms the Jacuzzi Covers form. The polystyrene should be tapered from 90 mm to 60 mm, this way the Jacuzzi Cover will form a type of roof on top of your Jacuzzi and, if outside, will allow for the water to run off. The 90 to 60 taper is the most practical, if you should decide to go for a 110 to 55 ratio, the polystyrene becomes too thin and can snap easily.

When you are certain your polystyrene is cut correctly, it’s time to wrap the polystyrene in an insulating black plastic, that will not only insulate the Jacuzzi Cover, but will also prevent the polystyrene from absorbing moisture. You will know that your Jacuzzi Cover has absorbed water, when it becomes impossible to carry your Jacuzzi Cover alone.

Before the Polystyrene is wrapped, the manufacturer uses 3 mm lip channel mild steel to reinforce the polystyrene in the middle to prevent sagging in the middle.

When both sides are wrapped and reinforced you can insert it into the Jacuzzi Cover that was stitched earlier. Getting it in can be tricky and you only get the hang of it after about 100 Jacuzzi Covers got made. You will need some type of a lever to wedge it in there.

Once the inserts are in, your Jacuzzi Cover should look something like the one bellow.